Installation technology and precision control of steel structure

Table of Contents

Benefits of Using Advanced Installation Technology in Steel Structure Construction

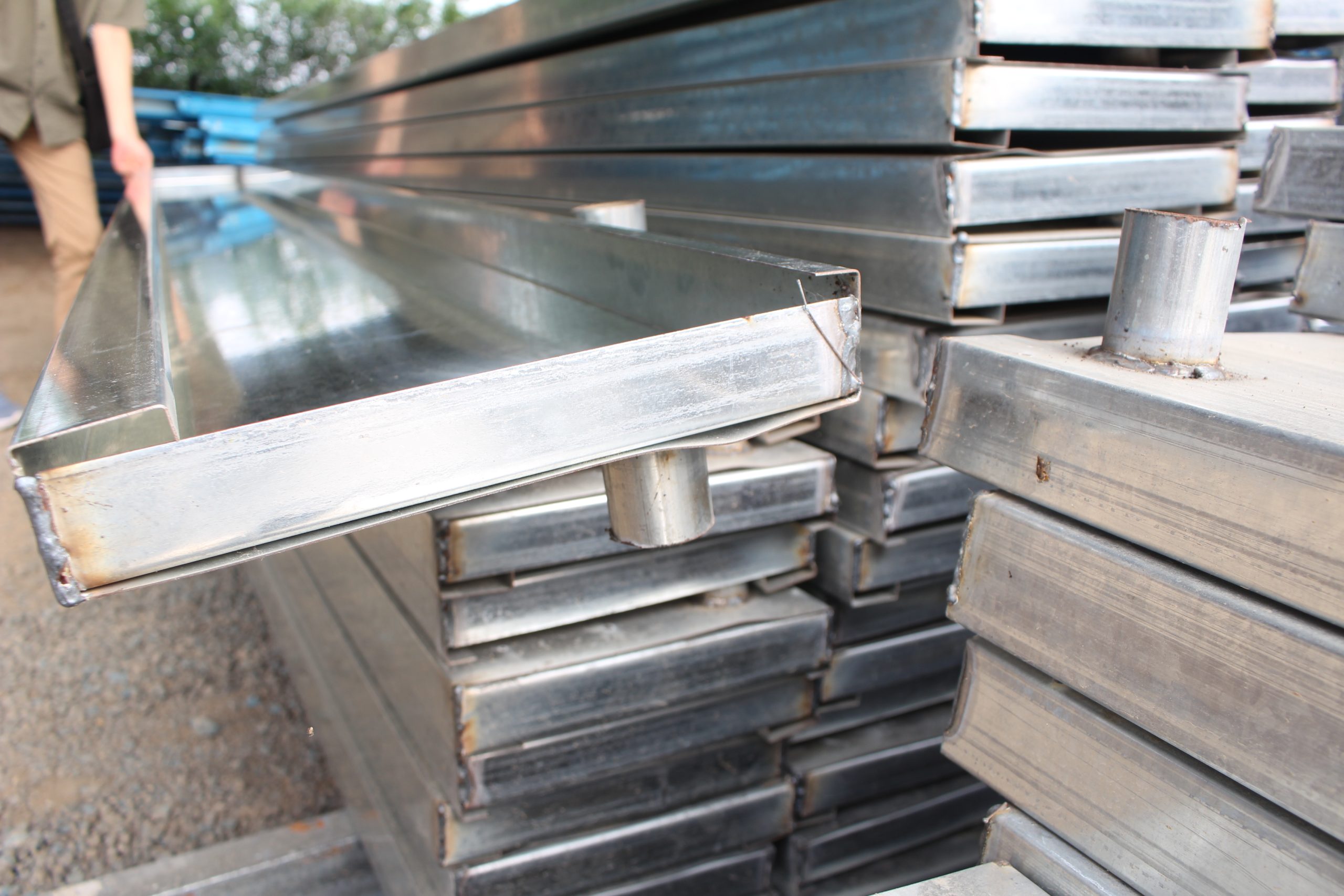

Steel structures have become increasingly popular in construction due to their durability, strength, and versatility. However, the installation process of steel structures can be complex and time-consuming. Advanced installation technology has revolutionized the way steel structures are constructed, offering numerous benefits in terms of precision control and efficiency.

One of the key benefits of using advanced installation technology in steel structure construction is the improved accuracy and precision it provides. Traditional installation methods often rely on manual labor, which can lead to human error and inconsistencies in the final product. Advanced technology, such as computer-aided design (CAD) software and robotic systems, allows for precise measurements and calculations, ensuring that each component of the steel structure is installed with the utmost accuracy.

Furthermore, advanced installation technology enables faster construction times, reducing overall project timelines and costs. Robotic systems and automated machinery can work around the clock, increasing productivity and efficiency on the construction site. This not only speeds up the installation process but also minimizes the risk of delays and disruptions, ultimately leading to a more streamlined and cost-effective construction project.

In addition to precision control and efficiency, advanced installation technology also enhances safety on the construction site. Robotic systems and automated machinery can perform tasks that would otherwise be dangerous or difficult for human workers, reducing the risk of accidents and injuries. By utilizing technology to handle the more hazardous aspects of steel structure installation, construction companies can create a safer work environment for their employees.

Another benefit of using advanced installation technology in steel structure construction is the ability to customize and optimize the design of the structure. CAD software allows for detailed planning and modeling of the steel structure, enabling architects and engineers to make adjustments and improvements before construction begins. This level of customization ensures that the final product meets the specific requirements and expectations of the client, resulting in a more tailored and high-quality steel structure.

Furthermore, advanced installation technology can also improve the sustainability of steel structure construction. By optimizing the design and installation process, construction companies can reduce waste and minimize the environmental impact of their projects. Additionally, the use of robotic systems and automated machinery can help conserve energy and resources, making steel structure construction more eco-friendly and sustainable in the long run.

Overall, the benefits of using advanced installation technology in steel structure construction are numerous and significant. From improved accuracy and efficiency to enhanced safety and sustainability, advanced technology has transformed the way steel structures are built. By embracing these technological advancements, construction companies can deliver high-quality, cost-effective, and environmentally friendly steel structures that meet the needs and expectations of their clients.

Importance of Precision Control in Steel Structure Installation Processes

Steel structures are a common sight in modern construction projects, from skyscrapers to bridges to industrial facilities. The strength and durability of steel make it an ideal material for supporting large loads and withstanding harsh environmental conditions. However, the successful installation of steel structures requires precise control and careful planning to ensure safety and structural integrity.

One of the key factors in the installation of steel structures is the use of advanced technology and precision control systems. These systems allow engineers and construction workers to accurately position and align steel components, ensuring that they fit together seamlessly and form a strong, stable structure. By using technology such as laser scanning, GPS tracking, and computer-aided design (CAD) software, construction teams can achieve a level of precision that would have been impossible just a few decades ago.

Precision control is essential in steel structure installation for several reasons. First and foremost, it ensures the safety of workers and the public. A poorly installed steel structure can collapse or fail, causing serious injury or even death. By using precise control systems, construction teams can minimize the risk of accidents and ensure that the structure meets all safety standards and regulations.

In addition to safety concerns, precision control also plays a crucial role in the overall quality and longevity of the structure. Steel structures are designed to last for decades, if not centuries, so it is essential that they are installed correctly from the outset. By using advanced technology and precision control systems, construction teams can ensure that every component is in the right place and properly aligned, reducing the risk of structural weaknesses or failures in the future.

Another benefit of precision control in steel structure installation is the ability to optimize the use of materials and resources. By accurately positioning steel components and minimizing waste, construction teams can reduce costs and improve efficiency. This is especially important in large-scale projects where even small savings can add up to significant financial benefits.

Furthermore, precision control allows construction teams to work more quickly and efficiently, reducing the overall timeline of the project. By using technology to streamline the installation process and eliminate errors, teams can complete their work faster and move on to the next phase of construction sooner. This can be a major advantage in competitive markets where speed and efficiency are key factors in winning contracts and satisfying clients.

In conclusion, the importance of precision control in steel structure installation cannot be overstated. By using advanced technology and precise control systems, construction teams can ensure the safety, quality, and efficiency of their projects. From skyscrapers to bridges to industrial facilities, precision control is essential for the successful installation of steel structures. By investing in the right technology and training for their teams, construction companies can achieve superior results and set themselves apart in a competitive market.