Quality control technology innovation of steel structure prefabrication and assembly construction

Inhoudsopgave

Benefits of Implementing Advanced Quality Control Technology in Steel Structure Prefabrication

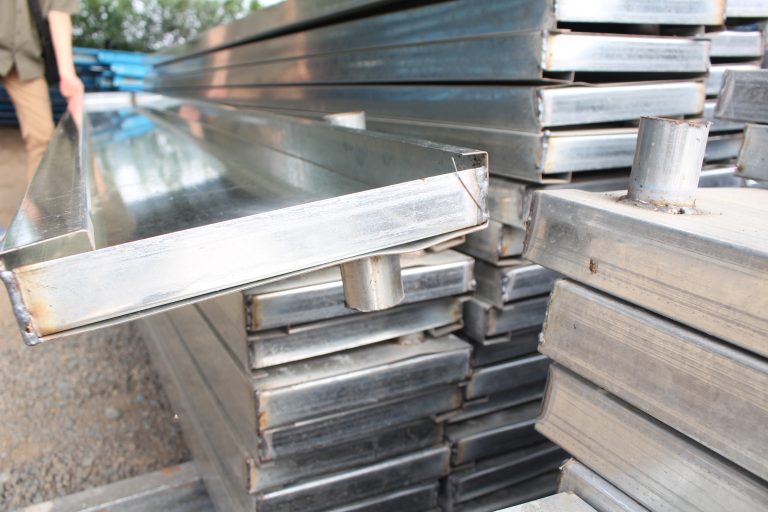

Steel structure prefabrication and assembly construction have become increasingly popular in the construction industry due to their efficiency, cost-effectiveness, and sustainability. However, ensuring the quality of prefabricated steel structures is crucial to the success of any project. Advanced quality control technology has played a significant role in improving the quality of steel structure prefabrication, leading to better construction outcomes and increased customer satisfaction.

One of the key benefits of implementing advanced quality control technology in steel structure prefabrication is the ability to detect defects and errors early in the manufacturing process. By using advanced scanning and imaging technologies, manufacturers can identify any imperfections in the steel components before they are assembled, allowing for timely corrections and preventing costly rework later on. This proactive approach to quality control helps to ensure that the final product meets the highest standards of quality and safety.

In addition to detecting defects, advanced quality control technology also allows for precise measurements and inspections of steel components. High-tech tools such as laser scanners and 3D modeling software enable manufacturers to accurately assess the dimensions and alignment of prefabricated steel structures, ensuring that they meet the exact specifications of the design. This level of precision not only improves the overall quality of the finished product but also helps to streamline the assembly process, reducing the risk of errors and delays.

Furthermore, advanced quality control technology can enhance the efficiency of steel structure prefabrication by automating certain aspects of the manufacturing process. Robotic systems and computerized machinery can perform repetitive tasks with greater speed and accuracy than human workers, leading to increased productivity and reduced labor costs. By incorporating automation into the production process, manufacturers can achieve higher levels of consistency and reliability in their prefabricated steel structures, resulting in a more uniform and reliable end product.

Another advantage of advanced quality control technology in steel structure prefabrication is the ability to track and monitor the entire manufacturing process in real-time. By using sensors and data analytics software, manufacturers can collect and analyze data on various aspects of production, such as temperature, humidity, and machine performance. This real-time monitoring allows for immediate identification of any issues or deviations from the desired quality standards, enabling prompt corrective action to be taken. By continuously monitoring and optimizing the production process, manufacturers can ensure that their prefabricated steel structures are of the highest quality and consistency.

Overall, the implementation of advanced quality control technology in steel structure prefabrication offers numerous benefits for manufacturers, contractors, and customers alike. By detecting defects early, ensuring precise measurements, automating production processes, and monitoring production in real-time, manufacturers can improve the quality, efficiency, and reliability of their prefabricated steel structures. This not only leads to better construction outcomes but also enhances customer satisfaction and trust in the product. As the construction industry continues to embrace innovation and technology, advanced quality control technology will play a crucial role in shaping the future of steel structure prefabrication and assembly construction.

How Automation and Robotics are Revolutionizing Quality Control in Steel Structure Assembly Construction

Steel structure prefabrication and assembly construction have long been a staple in the construction industry, offering numerous benefits such as reduced construction time, improved quality control, and increased safety on the job site. With advancements in technology, particularly in the fields of automation and robotics, the quality control process in steel structure assembly construction has been revolutionized, leading to more efficient and precise construction practices.

One of the key innovations in quality control technology for steel structure prefabrication and assembly construction is the use of automated inspection systems. These systems utilize advanced sensors and cameras to monitor the quality of materials and components throughout the construction process. By continuously monitoring the dimensions, alignment, and integrity of steel components, automated inspection systems can quickly identify any defects or deviations from the design specifications, allowing for immediate corrective action to be taken.

In addition to automated inspection systems, robotics have also played a significant role in improving quality control in steel structure assembly construction. Robotic arms equipped with specialized tools and sensors can perform a wide range of tasks, from welding and cutting to painting and finishing, with a level of precision and consistency that is unmatched by human workers. This not only ensures that the construction process is carried out with the highest level of accuracy, but also minimizes the risk of errors and defects that can compromise the structural integrity of the building.

Furthermore, the integration of artificial intelligence (AI) into quality control processes has further enhanced the efficiency and effectiveness of steel structure assembly construction. AI algorithms can analyze vast amounts of data collected from sensors and cameras in real-time, identifying patterns and trends that may indicate potential issues or areas for improvement. By leveraging AI technology, construction companies can make data-driven decisions that optimize the quality control process and ultimately lead to better outcomes for their projects.

Another important aspect of quality control technology innovation in steel structure prefabrication and assembly construction is the use of Building Information Modeling (BIM) software. BIM allows for the creation of detailed 3D models that accurately represent the design and construction of a building, enabling project teams to visualize and simulate the entire construction process before it even begins. By incorporating quality control parameters into the BIM model, construction companies can identify potential issues and conflicts early on, allowing for timely adjustments to be made to ensure the quality and integrity of the final structure.

Overall, the integration of automation, robotics, AI, and BIM technology into the quality control process of steel structure prefabrication and assembly construction has revolutionized the way construction projects are planned, executed, and monitored. By leveraging these advanced technologies, construction companies can achieve higher levels of precision, efficiency, and safety in their projects, ultimately delivering better quality buildings to their clients. As technology continues to evolve, the future of steel structure assembly construction looks brighter than ever, with endless possibilities for innovation and improvement in quality control practices.